Interpretation of 2024 GAC Toyota Science and Technology Open Day

On June 28, GAC Toyota broke the convention for the first time in 20 years, and demonstrated its technical achievements for the first time, issuing the theme of "Creating a hybrid balance era". Focusing on a number of intelligent, electric technology and future planning layout, below, let's interpret its fifth generation THS technology and a new generation of all-solid-state batteries.

1. The fifth generation of intelligent electric hybrid

Toyota's leading hybrid technology is not a temporary Internet celebrity, more is the market's long red, 5 generations of evolution, the earliest, the largest sales, the most patented technology, the system is reliable, through miniaturization, lightweight, precision, and constantly improve performance and reduce fuel consumption.

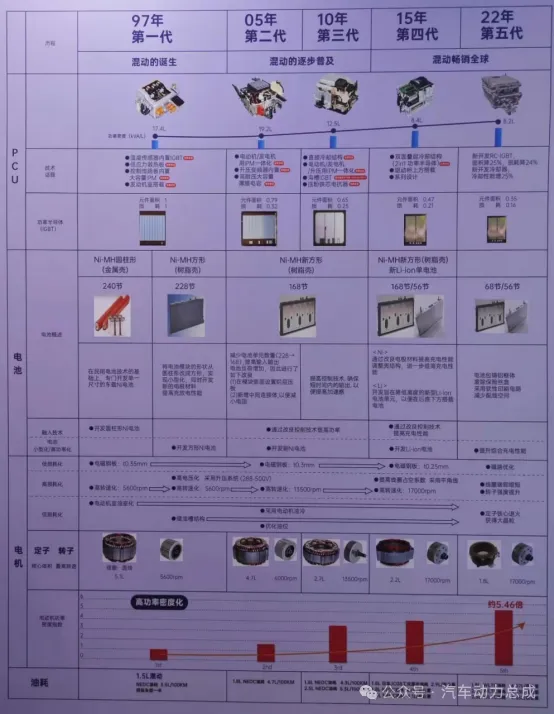

From the first generation of THS technology development, temperature sensor built-in IGBT, low stress heat dissipation plate, control circuit board built-in large capacity IPM have become a technical topic, power semiconductor IGBT: component area 1, loss 1, Ni-MH cylindrical (metal shell) 240 sections, to the fifth generation, power semiconductor IGBT: Element area 0.35, loss 0.16, Ni-MH cylindrical (metal shell) 68/56 section, through the data is not difficult to see, the power density of the battery motor gradually increased, IGBT power semiconductor component area and loss gradually reduced. At present, the 1.8L, 2.0L and 2.5L hybrids on the Relin and Camry are all fifth-generation technologies. The fifth generation technology mainly changes the structure and process of the battery pack in the battery part, and replaces the nickel-metal hydride battery with a ternary lithium battery, which has better charging performance.

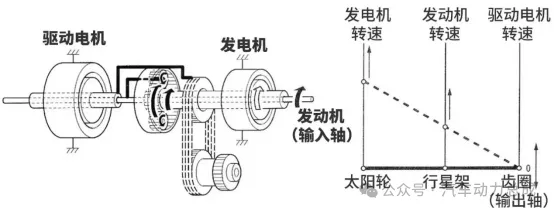

According to the classification of power system structure, hybrid electric vehicles (including plug-in hybrid) involve the integration with the transmission power source (engine and transmission), and each enterprise based on its own technical resources, derived various configurations, divided into series, parallel and hybrid. The driving force of the series hybrid system comes from the motor, and there is only one driving system; The driving force of the parallel hybrid system is supplied by the motor or engine simultaneously or separately, and there are two sets of driving systems; The hybrid type has both series and parallel system mechanisms, and has a variety of hybrid driving modes. Toyota uses a planetary gear set to achieve a series parallel function of the hybrid called power shunt.

Different hybrid solutions can include different numbers of motors (single motor, double motor) and different motor positions (P0, P1, P2, P3 and P4). In the hybrid technology path, the Japanese system leads the hybrid type of oil-electric hybrid, the German system mainly focuses on the parallel P2 single motor plug-in hybrid, the American system mainly focuses on the hybrid hybrid, and the independent brand chooses the two hair force, which not only meets the current needs of new energy points, but also takes into account the future product and technical layout.

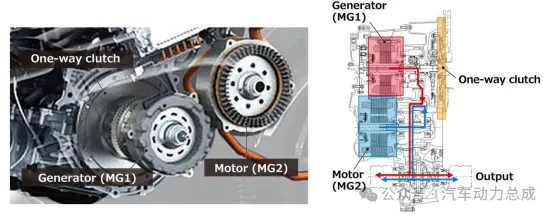

The core of the Toyota THS system is the coupling of the engine, generator MG1 and motor MG2 through the planetary platoon power distribution device, which has the advantages of:

(1) Simple single-planet row input single-mode eCVT architecture, parallel axis offset, smooth planetary gear switching, can ensure the operation of different working conditions

(2) The internal combustion engine has high fuel efficiency, good system oil saving, and high fuel saving rate in urban conditions

(3) The A-class car application is cost-effective, and the gearbox has no shift actuator

The disadvantages are:

(1) Complex mechanical structure, EV mode will still drive the engine planetary gear, there is energy loss

(2) The lack of direct drive mode, equivalent to 1 gear eCVT + 1 gear fixed speed ratio parallel or engine direct drive, high-speed conditions lack of fuel economy, climbing and sustained power is not as good as the general dual-mode EVT

Power source of Toyota THS system under different working conditions:

(1) Under static low power condition, MG1 rotates to the lowest working speed of the engine, the engine starts, and then the engine drives MG1 to charge the battery, and MG2 is energized to output reverse torque and fix the external gear ring

(2) Starting/low speed and low load driving conditions. The MG2 takes power from the battery and drives the wheels, the MG1 generator idles and the engine stalls

(3) Under normal medium speed conditions. The engine starts (the wheels are driven by the fixed tooth ratio of the planetary gear), the engine drives the MG1 to generate electricity and the MG2 motor drives the wheels

(4) Heavy load driving conditions. The engine accelerates to drive the MG1 and MG2, the MG2 drives, and the MG1 is used for charging

(5) Under rapid acceleration conditions. MG1 rotates forward to act as an electric motor, MG2 draws maximum power from the battery to drive the wheels, and the engine also drives the wheels at maximum power

(6) Braking or coasting conditions. The engine is turned off, and the wheel drive MG2 is charged for kinetic energy recovery

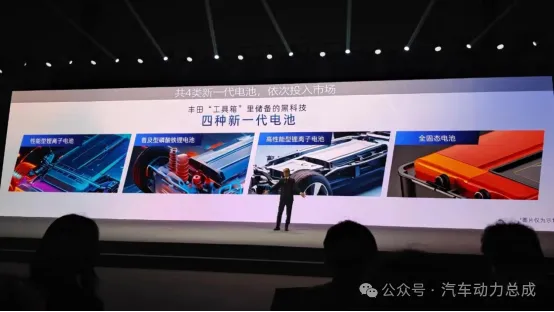

2. Four new generation battery technologies

At the meeting, Toyota also announced its reserve of black technology, four new generation battery technologies: performance lithium-ion batteries, popular lithium iron phosphate batteries, high-performance lithium-ion batteries, all-solid-state batteries.

Performance lithium-ion battery: expected to be launched in 2026, the range of more than 1,000 kilometers, from 10% to 80% fast charge only 20 minutes, the cost is 20% lower than the current bZ4X.

Popular lithium iron phosphate battery: is expected to be launched in 2026-2027, using the "bipolar technology", the original battery is connected by an independent cell through the wire, the bipolar is the connection line and the cell shell package removed, directly the multiple cell connection package in a battery pack, in a limited space, to improve the battery energy density. The range of the BEV is more than 600km, the cost is reduced by 40% compared with the cash bZ4X, and the fast charging time is less than 30 minutes from 10% to 80%.

High-performance lithium-ion battery: it is expected to be launched in 2027-2028, with a driving range of more than 1000km, a 10% cost reduction, and a fast charge time of less than 20 minutes from 10% to 80%.

All-solid-state battery: It is fully promoting research and development with the goal of launching in 2027-2028, and the mileage of models equipped with solid-state batteries will reach more than 1,000 kilometers, achieving fast charging in just 10 minutes.

Note: This article cites data and images from the Internet