Great Wall Motors releases Hi4-Z technology analysis for pan off-road super hybrid architecture

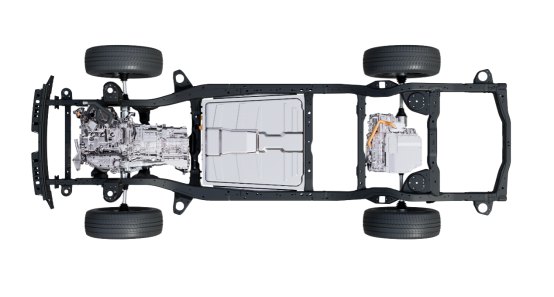

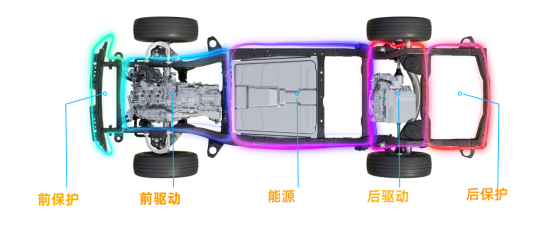

On December 3rd, Great Wall Motors unveiled its Hi4-Z ultra hybrid architecture specifically designed for off-road use at the Tank 500 pre-sale event, which is sure to be popular, H (Hybrid) represents hybrid, i (intelligent) represents intelligence, 4 represents (4WD) four-wheel drive system, Z (zenith) represents peak, symbolizing another peak in Great Wall Motors' exploration of new energy hybrid architecture. Adopting a hybrid architecture consisting of 2.0T and 3.0T high-power engines, longitudinal power split, 3-speed transmission, large capacity battery, and front and rear dual motors. The 3.0T system has a comprehensive power of 715kW and a comprehensive torque of 1375N · m, while the 2.0T system has a comprehensive power of 635kW and a comprehensive torque of 1195N · m.

Below we will provide a detailed analysis of this architecture:

(1) Detailed explanation of core components

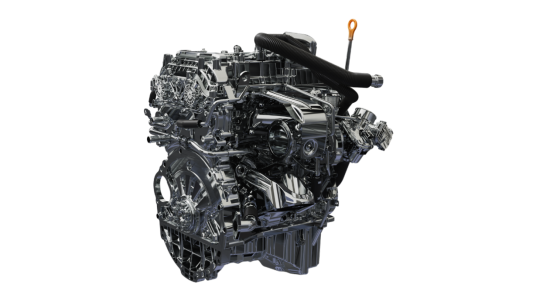

① Vertically mounted 2.0T/3.0T high-power engine.

The maximum power torque of the 2.0T engine is 180kW/380N · m, using low-pressure EGR, Miller cycle and other technologies, with a maximum off-road engineering thermal efficiency of 40%. The 3.0T engine adopts dual turbocharging, with a maximum power torque of 260kW/560N · m, which is the highest engineering thermal efficiency of 38.5% in the same class.

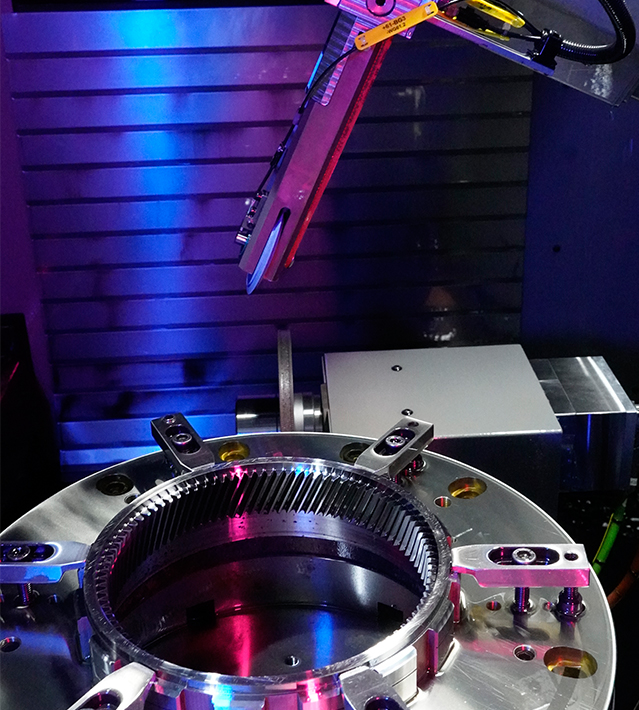

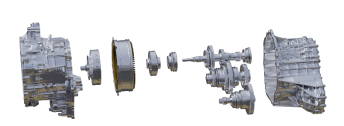

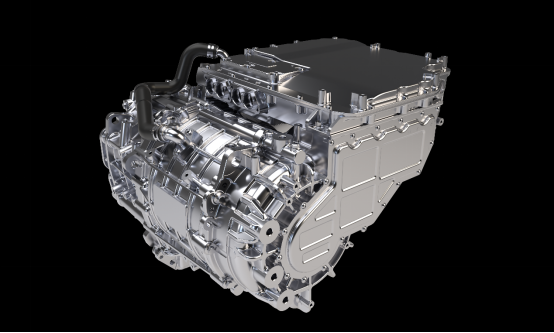

② Vertical power split+3-speed transmission

The transmission integrates components such as clutch, 215kW high-power motor, planetary gearbox, planetary gearbox locking mechanism, and 3-speed parallel shaft, with a transmission efficiency of 98%. More than 20 components and motors are nested in a 560mm space, and the front drive shaft universal joint is welded together with the transmission gear, making the gearbox 20% shorter than the single gear configuration.

The front motor adopts flat wire winding, with a motor efficiency of over 98%, a maximum power of 215kW, and a maximum torque of 400N · m

The design of planetary gear shift+3 gears enables the Hi4-Z system to have all hybrid configurations available on the market. With the cooperation of the planetary gear shift locking mechanism, it can flexibly switch between five modes: power splitting, series connection, parallel connection, direct drive, and pure electric.

The 3-speed economy gear is used at high speeds, with low energy consumption. The 2nd gear is used for daily acceleration, with fast acceleration. The 1st gear is used for escape. With a speed ratio of over 20 times, it can achieve a 20 fold amplification of torque to the wheel end.

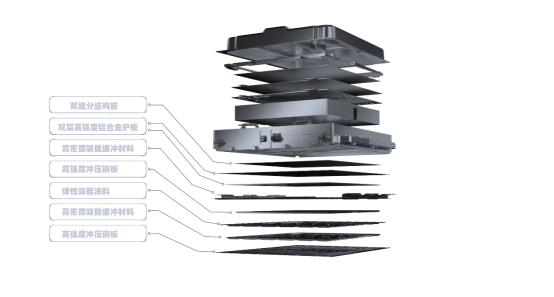

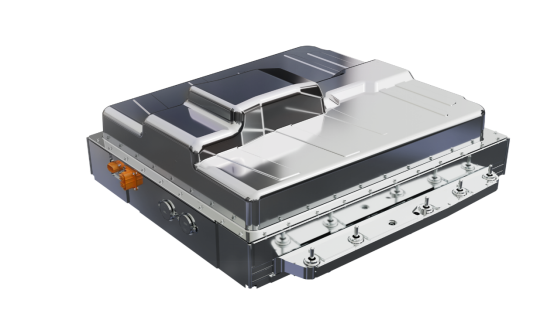

③ Large capacity and high-density battery system

The Hi4-Z is equipped with a 59.05 degree battery pack, with a cell density of 234Wh/kg and a volume density of 232Wh/L. Under WLTC conditions, the pure electric range is 201km, and the system's comprehensive range can reach 1100km+.

The battery cell adopts fast charging high rate battery cell, 3C charging rate, maximum fast charging power of 163kW, and discharge power of 600kW. Charging under 30% -80% SOC conditions only takes 15 minutes, and it can travel 120km on pure electric power.

The battery design has 8 layers of vertical safety protection, which can protect the battery pack from various impacts under complex working conditions. Four layers of lateral safety protection are installed to reduce lateral collision injuries that are most likely to cause battery compression deformation, making 8+4 safer. Adopting a super IP68 waterproof rating, the battery can be left at a water depth of less than 1m for 48 hours without any water entering. All functions are normal, exceeding the industry standard of 96 times for 0.5 hours.

Full time automatic monitoring: BMS monitors the voltage and temperature of battery cells 24 hours a day, covering scenarios such as driving, parking, charging, and discharging. When thermal runaway occurs during driving, a thermal runaway signal can be sent to the vehicle controller within 0.2 seconds, and a high-voltage cut-off command can be issued 0.1 seconds after parking. When the vehicle is turned off and left idle, the BMS detects the voltage and temperature of the battery cells every 8 seconds. When a vehicle collides, ABM controls the airbag to deploy through industry-leading high-voltage collision rapid discharge technology, while also controlling the intelligent fuse to issue a high-voltage cut-off command. The signal transmission takes about 0.02 seconds, and the cut-off only takes 0.003 seconds, avoiding the risk of high-voltage electric shock.

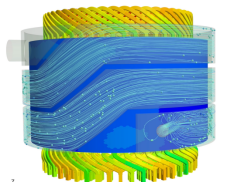

④ High performance rear axle motor

Adopting a super 800V high-voltage system, equipped with third-generation semiconductor technology, and using Great Wall's self-developed 1200V silicon carbide electronic control module, the controller efficiency is 99.8%, and the motor efficiency is greater than 98%. The internal adopts a two-stage reduction mechanism, with the first gear ratio also greater than 20, which can be combined with the front axle low-speed gear to form a 4L mode, achieving a 20 fold amplification of front and rear power to the wheel end.

It also integrates a boost module internally, and when charging with a low-voltage pile, the maximum fast charging power exceeds 120kW.

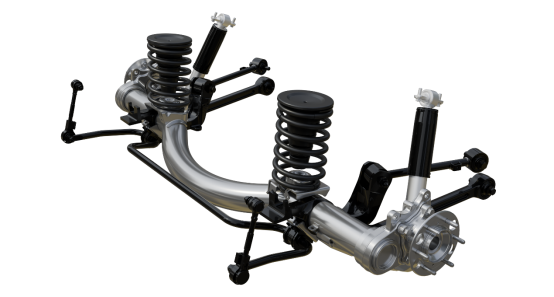

⑤ Five link Dion bridge off-road suspension

The left and right wheels are connected by a very thick (φ 90 × 7.5) circular high-strength steel pipe, using 4000 ton hydraulic integrated molding technology to press the bent beam together, with a bending beam strength of 1000MPa. The unsprung mass is reduced by 35kg, effectively reducing the variation of wheel dynamic load on uneven road surfaces, improving the tire's ground contact/grip ability and driving comfort, while retaining the dynamic ground clearance ability of the overall bridge, providing a great suspension stroke.

(2) System core analysis:

① Strong power

The maximum horsepower of the system is 972, and the full power of the front and rear motors is 455kW. The 600kw battery can support full load output of the front and rear motors, with 0-100 acceleration and full charge in 4 seconds and 0 to 100 acceleration in 5 seconds.

Hi4-Z can output at full capacity in desert direct pull, with a maximum climbing slope of 100%. The configuration design includes a large displacement engine and a power split+3-speed front wheel drive module. When powered, it provides powerful output through power split, and supports 67% of long-term continuous climbing in desert direct pull.

② Strong power continuity

0-100 acceleration for 20 consecutive tests without attenuation. When feeding power, a power split mode is adopted. While a portion of the engine's power drives the vehicle, a portion of the power is generated to power the P4 motor to drive the rear axle, and the remaining electricity is charged to achieve strong power replenishment capability. Both the front and rear motors adopt a composite cooling method of water cooling and oil cooling, which has better cooling effect and sustainable optimization performance.

③ Better economic efficiency

The comprehensive efficiency of the power supply city has been greatly improved, with an average fuel consumption reduction of about 8.25%. The Hi4-Z, with its planetary transmission structure and three speed front wheel drive module, can achieve power splitting, keeping the engine in the high-efficiency range at all times. Moreover, most of the engine power remains in direct drive, with a short transmission link and a city fuel consumption reduction of 0.7L/100km.

Under high-speed and high load conditions, the overall efficiency is greatly improved, and the average fuel consumption is reduced by about 11.04%. The engine is driven directly by locking the planetary gear, and with the design of the three speed front wheel drive module, the engine always runs in the high-efficiency range, with a short transmission link, high comprehensive efficiency, low energy loss, and a 1.3L/100km reduction in high-speed fuel consumption.

In off-road driving scenarios, the engine is directly driven, the operating point is in the high efficiency zone, the power transmission chain is short, and the overall efficiency is higher. Compared with single gear series parallel driving, the actual fuel consumption of crossing the Bilutu Peak is reduced by 12L/100km.

By utilizing strategies such as predictive energy management, intelligent energy recovery, and intelligent thermal management under intelligent energy management, the efficient operation of components such as engines, three electric systems, and compressors can be achieved, resulting in a further reduction of energy consumption by 8% to 15%.

④ Architecture Security

The system adopts a non load bearing body, with a platform architecture consisting of 2 vertical and 9 horizontal beam frames, made of 99% ultra strong steel and high-strength steel.

The above is a detailed analysis of the Hi4-Z hybrid system.

Note: The data and images cited in the article are sourced from the internet