Solid state battery technology analysis and market analysis

The L6Max Light-year version released by Zhiji Automobile is equipped with ultra-fast rechargeable solid-state batteries, which has attracted the attention of the industry. Solid-state batteries have high safety, high energy density and fast charging potential, and are considered to be the hope of future innovation in the automotive industry.

A solid state battery is a battery that uses a solid electrolyte. The lithium battery is composed of four main materials: positive electrode material, negative electrode material, electrolyte and diaphragm, which play the role of transporting ions and conducting current. However, in liquid electrolytes, organic solvents are inflammable, highly corrosive, and have poor oxidation resistance and cannot solve the lithium dendrite problem, so there is a risk of thermal runaway, which also limits the use of high-energy materials such as high-voltage positive electrodes and lithium metal negative electrodes. Solid-state batteries replace the electrolyte, partly or entirely, with a solid electrolyte. It can greatly improve the safety and energy density of the battery, which is the long-term potential technical direction of the existing material system.

1. Liquid, semi-solid and solid state batteries

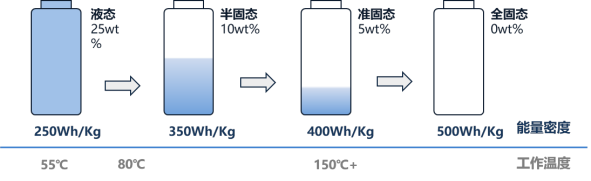

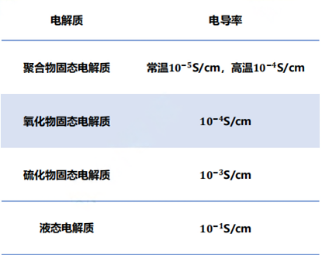

According to the electrolyte classification, the battery can be subdivided into liquid (25wt%), semi-solid (5-10wt%), quasi-solid (0-5wt%) and all-solid (0wt%) four categories, of which semi-solid, quasi-solid and all-solid three are collectively referred to as solid-state batteries. Polymers, oxides and sulfides are the three main types of solid electrolytes for solid-state batteries.

Semi-solid battery: Compared with the liquid battery, the semi-solid battery reduces the amount of electrolyte and increases the polymer + oxide composite electrolyte, wherein the polymer is filled in the form of frame network, and the oxide is mainly added in the form of diaphragm coating + positive and negative electrode coating. In addition, the negative electrode is upgraded from the graphite system to the pre-lithium silicon based negative electrode/lithium metal negative electrode, and the positive electrode is upgraded from high nickel to high nickel and high voltage/lithium rich manganese base. The diaphragm is still retained and coated with a solid electrolyte coating, the lithium salt is upgraded from LiPF6 to LiTFSI, and the energy density can reach 350Wh/kg or more. All-solid-state battery: Compared with the liquid battery, the all-solid-state battery cancels the original electrolyte, chooses the polymer/oxide/sulfide system as the solid electrolyte, and divides the positive and negative electrodes in the form of a thin film, thus replacing the role of the diaphragm. The upper limit of the polymer performance is lower, the oxide progress is faster, and the sulfide has the greatest potential in the future. The negative electrode has been upgraded from the graphite system to the pre-lithium silicon based negative electrode/lithium metal negative electrode, and the positive electrode has been upgraded from high nickel to ultra-high nickel/lithium nickel manganate/lithium rich manganese base, and the energy density can reach 500Wh/kg.

2.Advantages of solid-state batteries

(1)Solid state batteries have high safety

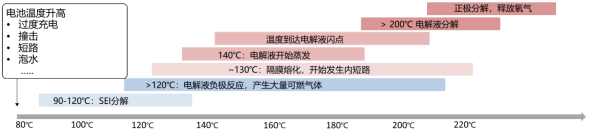

With the increasing energy density of batteries, the risk of thermal runaway of batteries shows an increasing trend.

From the perspective of thermal runaway, the battery should operate at less than 60 ° C, but due to internal short circuit, external heating, mechanical abuse and other factors, so that the battery temperature rises to 90 ° C, at this time the SEI film on the surface of the negative electrode begins to dissolve, causing the lithium carbon to be directly exposed to the electrolyte, the two react quickly to release heat, produce a large number of flammable gases, the diaphragm then melts, the battery forms an internal short circuit. The temperature rapidly rises to 200 ° C, prompting the electrolyte to vaporize and decompose, the positive electrode interprets oxygen, and the battery burns violently or explodes.

Solid-state batteries have intrinsic safety and are a major consideration for automakers in the short term.

① Non-flammable, thermal stability: liquid electrolyte is flammable and volatile, decomposition temperature is about 200 ° C (diaphragm 160 ° C), and there is a security risk of corrosion and leakage. The solid electrolyte has non-combustible, non-corrosion, non-volatilization and other characteristics, the decomposition temperature is greatly increased, can be operated at a higher rate and higher temperature, while the internal liquid does not flow, the battery can withstand piercing, cutting, cutting, bending, thereby greatly reducing the risk of thermal runaway.

② Lithium dendrites: In liquid batteries, the growth of lithium dendrites is easy to puncture the diaphragm, resulting in short circuit, while solid electrolytes have high mechanical strength, lithium dendrites grow slowly and are difficult to Pierce, thereby improving the safety performance of the battery.

(2)Solid-state batteries have a high energy density

Solid electrolyte is compatible with positive and negative electrodes with high specific capacity, which greatly improves the energy density of the battery, which is the main consideration for the automaker in the long term. Solid state battery on the basis of taking into account the safety, can achieve a breakthrough in energy density, liquid battery can reach 250Wh/kg+, semi-solid can reach 350Wh/kg+, quasi-solid can achieve 400Wh/kg+, all-solid can break through 500Wh/kg, so as to improve the endurance level, is expected to solve the electric vehicle mileage, safety of the two core pain points.

Solid electrolyte itself can not improve the energy density, and due to more stable, safer, electrochemical window width (more than 5V) and other properties, so it can be compatible with high specific capacity of positive and negative electrodes, such as high voltage positive electrode, lithium rich manganese base, silicon negative electrode, lithium metal negative electrode and other materials, and then greatly improve the energy density of the cell; The separator function of the electrolyte can be combined into one, greatly reducing the positive and negative electrode spacing, thereby reducing the thickness of the battery, and therefore increasing the energy density of the battery cell; Due to the non-fluidity of the electrolyte, the series and voltage boost inside the cell can be realized, which can reduce the packaging cost of the cell and increase the volume energy density. The safety of the solid electrolyte can reduce the system thermal management system requirements, significantly improve the group efficiency, and thus increase the Pack energy density.

3.Disadvantages of solid-state batteries

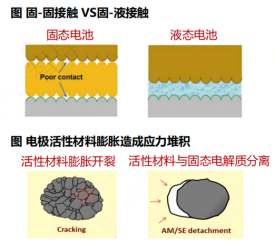

(1)Solid state battery has low ionic conductivity and poor cycle life, solid state battery interface is solid-solid contact, low ionic conductivity, poor interface stability, circulation, fast charge and other problems, restricting its commercialization process.

In solid state batteries, the interface contact between the electrode and the electrolyte changes from solid-liquid contact to solid-solid contact, and because the solid phase is non-wettability, the contact area is small and the interface resistance is higher. At the same time, a large number of grain boundaries exist in the solid electrolyte, and the grain boundary resistance is often higher than the resistance of the material body, which is not conducive to the transmission of lithium ions between the positive and negative electrodes, thus affecting the fast charge performance and cycle life.

Solid-solid contact is rigid contact, which is more sensitive to changes in the volume of the electrode material. During the cycle, it is easy to cause the contact between the electrode particles and the electrode particles and the electrolyte to deteriorate, resulting in stress accumulation, resulting in attenuation of electrochemical performance, and even the appearance of cracks, resulting in rapid attenuation of capacity, resulting in poor cycle life.

(2)Solid electrolytes contain rare metals, and the cost is significantly higher than that of liquid batteries, mainly reflected in solid electrolytes and positive and negative electrodes. Solid electrolytes are currently difficult to thin, some of the rare metal raw materials used in high prices, oxide electrolytes containing zirconium, sulfide electrolytes containing germanium, superimposed as a high energy density of the use of highly active positive and negative electrode materials are not mature, copper lithium composite belt price of 10,000 yuan /kg, all solid state production process, cost and quality control also put forward more stringent requirements. The production equipment replacement rate is large, and the cost of all-solid-state batteries is expected to be significantly higher than that of existing liquid batteries.

4.Solid state battery industry status and development trend

Solid-state battery technology development and application is expected to show a cascade penetration trend. It is expected that the technical iteration path from liquid battery to solid state battery roughly follows the order of "solid electrolyte → new negative electrode → new positive electrode".

Stage 1: Solid electrolyte is introduced, a small amount of electrolyte is retained, the positive and negative electrodes are still ternary + graphite/silicon negative electrodes, and the negative electrode pre-lithium technology is used to improve the energy density;

Stage two: Gradually replace the electrolyte with a solid electrolyte, replace the graphite/silicon negative electrode with metal lithium, and the positive electrode is still a ternary material;

Stage 3: Gradually reduce the thickness of the solid electrolyte, and replace the positive electrode with sulfide/lithium nickelmanganate/lithium rich manganese base materials.

Semi-solid: Safety, energy density and economy, the first to enter the mass production stage. Semi-solid batteries are the first to enter the mass production stage by reducing the liquid electrolyte content and increasing the solid electrolyte coating, combining safety, energy density and economy. The all-solid-state battery process is not mature and is still in the laboratory research and development stage, while semi-solid-state batteries have entered the mass production stage. The semi-solid battery retains a small amount of electrolyte, which can alleviate the ion conductivity problem. At the same time, the solidification process is used to convert the liquid electrolyte into a polymer solid electrolyte, and the superimposed oxide solid electrolyte is coated with positive/negative electrode/diaphragm, which improves the safety/energy density of the battery. At the same time, it is compatible with the process equipment of traditional lithium batteries, so as to achieve the effect of easier mass production and lower cost. It is expected that the cost of semi-solid batteries after large-scale production is 10-20% higher than that of liquid lithium batteries.

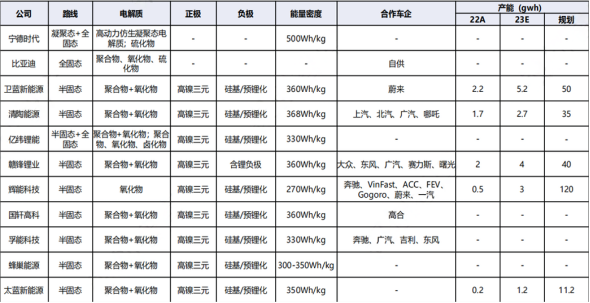

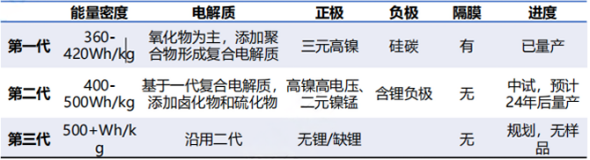

5.Solid state battery industry situation

The solid-state battery technology iteration is based on the liquid system, and the sequence follows the solid-state electrolyte - new negative electrode - new positive electrode. Mainstream manufacturers according to the semi-solid to all-solid development path layout, the core change is the introduction of solid electrolyte, electrolyte is expected to be from the semi-solid polymer + oxide route, to the semi-solid oxide/all-solid route, and then to the sulfide all-solid route iteration; The negative electrode is upgraded from graphite to silicon based negative electrode, lithium containing negative electrode, and then to metal lithium negative electrode; The positive electrode iterates from high nickel ternary, to high voltage high nickel ternary, ultra-high nickel ternary, and then to spinel lithium nickel-manganate, layered lithium rich manganese base and other new positive electrode materials. The diaphragm is upgraded from the traditional diaphragm to the oxide coated diaphragm and then to the solid electrolyte membrane.

In terms of industry chain, the battery end enterprises mainly include Ningde Times, BYD, Weilan New Energy, Qingtao Energy, Yiwei Lithium Energy, Ganfeng Lithium Industry, Huineng Technology, Guoxuan High-tech, Funeng Technology, Honeycomb Energy, etc.; Solid electrolyte enterprises mainly include Tianmu Lead, Blue Gu New Energy, Aoke shares, Shanghai Zeba, Jinlongyu, Ruitai new materials, etc.; Solid electrolyte precursor zirconium source/germanium source enterprises include Dongfang Zirconium Industry, Sanxiang New Materials, Yunnan Germanium industry, Chihong zinc Germanium and so on; Negative electrode enterprises have Lanxi Zhide, Beitrui, Xiang Fenghua, etc.; Positive enterprises have Rong Bai technology, Dang Sheng technology, etc.; Diaphragm enterprises have Njie shares, etc.; In addition, vehicle enterprises actively participate in the way of self-research or capital increase, and the representative companies are Toyota, Nissan, Honda and so on.

(1)Nind era

① Condensed matter battery

Condensed matter battery introduced by Ningde Times has both high specific energy and high safety, and can be quickly mass-produced with an energy density of up to 500Wh/kg. The battery uses a high dynamic bionic condensed matter electrolyte to build a nanoscale adaptive network structure to adjust the interchain interaction force, enhance the stability of the microstructure, improve the battery power performance, and improve the transport efficiency of lithium ions. In addition, condensed matter batteries have also polymerized a series of innovative technologies, including ultra-high specific energy positive electrode, new negative electrode, isolation film and new technology, so that they have excellent charge-discharge performance and high safety performance. At present, Ningde Times is carrying out the cooperative development of civil electric manned aircraft project, implementing aviation level standards and tests to meet aviation level safety and quality requirements. At the same time, Ningde will also launch a car-scale application version of condensed matter batteries.

② Sulfide all-solid-state battery

The layout of the most potential sulfide all-solid electrolyte, Ningde times since 13 years to apply for solid-state battery related patents, with many years of technical reserves, of which 9 patents contain sulfide solid electrolyte, the patent content includes sulfide based solid electrolyte, positive electrode sheet, solid state battery, battery material recycling and other aspects. The company currently has laboratory samples of high-energy-density solid-state batteries, but commercialization is still more than five years away. For the high-end market, Ningde times will continue to invest in the research and development of all-solid lithium metal and other new material technology, lithium metal negative material as the development direction, the positive material from the traditional ternary to the high pressure ternary, metal-free material iterative upgrade, through continuous research process problems and key technologies, Strive to achieve a real sense of ultra-long life, safe and cost-competitive lithium battery technology by 2030.

(2)BYD

Since 2011 to apply for solid-state battery related patents, as of March 23, has applied for more than 50, more than 30 patents authorized, more than 10 patents in the application, patent reserve is rich. Byd's technical route includes polymers, oxides, sulfides and composite solid electrolytes, of which the polymer route mainly includes PEO and polyoleate esters, oxides, sulfides and composite solid electrolyte routes have a wide range of research, and multiple routes are carried out simultaneously and constantly upgraded and iterated. In addition, the positive/negative electrode materials are continuously optimized, and the ternary positive electrode is coated with sulfide electrolyte and molybdate to improve ion transport and cycling performance. The negative electrode adopts silicon-based core-shell structure and antimony/bismuth lithium alloy to improve ion/electron conductance and electrochemical performance. Application of solid electrolyte related patents covering solid electrolyte materials, positive/negative electrode material modification and modification, battery structure, battery pack and module design, etc., a wide range of patents, rich technical reserves, in line with the company's development strategy, combined with the traditional battery pack to CTC route development trend, it is speculated that the third generation of blade batteries may use solid soft packs.

(3)Qingtao Energy

Qingtao (Kunshan) Energy Development Co., Ltd. was founded in 2016, led by Nan Cewen, academician of Chinese Academy of Sciences and professor of Tsinghua University. The team has been working on solid-state batteries for more than 20 years and has been authorized more than 300 patents. The company has broken through the core solid electrolyte (LATP, LLTO, LLZO) production technology, and can prepare the composite electrolyte film containing oxide particles uniformly dispersed on the polymer skeleton through high-speed dispersion, casting molding and other methods, with powder, slurry, electrolyte coating and other complete processes, the first to achieve the mass production of semi-solid batteries. The company has received strategic investment from BAIC, SAIC, GAC and other companies, and established long-term cooperative relations with Nezha and other car enterprises.

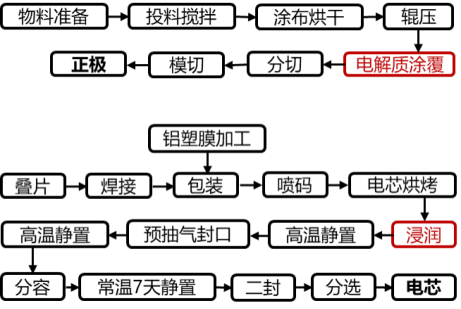

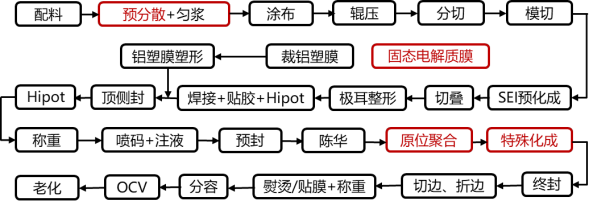

The production process of Qingtao energy positive electrode and battery cell is shown in the following figure:

In November 2018, Qingtao Energy built the first solid state battery mass production line (0.1gwh, 400Wh/kg), which is applied to special power supplies, high-end digital and other consumer fields. In July 2020, BAIC and Nezha U pure electric sample vehicles equipped with Qingtao solid-state battery system rolled off the assembly line, and in November 2021, lightweight solid-state battery products joined hands with GAC Aean to debut at the auto show, with a cell energy density of 320Wh/kg. In December 2021, it cooperated with SAIC to complete the real vehicle verification of 368Wh/kg, 1083kmCLTC endurance, and was first applied to the new model of SAIC's own brand in 2023. In November 22, the first set of solid state battery system for mass production commercial vehicles jointly developed with Beiqi Foton has completed commissioning and officially rolled off the assembly line. The company has a production capacity of 1.7gwh by the end of 2022 and a long-term planned production capacity of 35gwh. Self-developed and self-produced solid electrolyte powder materials, in addition to the strategic cooperation with Liyuanheng, Dangsheng Technology, Xiangfenghua Da Cheng, to ensure equipment and positive and negative electrode material supply

(4)Hundred million lithium energy

Founded in 2001, in 2009 in Shenzhen GEM listed in the first batch, after 23 years of rapid development, has become a globally competitive lithium battery platform company, while with consumer batteries, power batteries, energy storage battery core technology and comprehensive solutions.

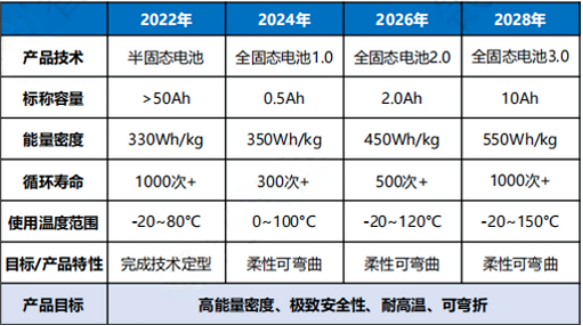

In December 2022, Yiwei Lithium Energy announced semi-solid and all-solid state battery products and future technical layout in the new technology and new product conference, the first generation of semi-solid technology is based on 50Ah soft pack battery, energy density of 330Wh/kg, cycle life of more than 1000 times, and the battery operating temperature range extends to -20-80 ℃. The product has been designed and finalized in 22 years and is currently in the stage of loading and testing.

The company's existing all-solid-state thin-film soft-pack battery technology is based on halide system, which can adapt to special high temperature and bending conditions, and can be stably discharged at 150 ° C high temperature with high nickel anode, and flexible technology enables the battery to be normally charged and discharged at 120° bending conditions. The company plans to complete the all-solid-state battery 1.0 technology research and development in 24 years, the energy density of 350Wh/kg, cycle life of more than 300 times, the first generation of all-solid-state battery products in the robot/fire equipment, built-in medical, VR/ curved screen and other high-end consumer applications have great potential. The company has decades of research and development experience in the field of solid electrolyte, the company's solid-state technology iteration will be divided into three stages, the future will focus on the development of oxides, sulfides, halide routes, aimed at creating high specific energy, extremely safe solid-state battery system. The goal is to achieve all-solid-state battery 3.0 technology iteration in 28 years, increase the energy density to 550Wh/kg, cycle life 1000 times +, and have high safety, high flexibility, high temperature resistance and other characteristics to meet the needs of the power battery field. See Table 20 for the technical layout route of Yiwei lithium energy solid state battery:

Table 20: Yiwei lithium energy solid state battery technology layout route

(5)Guo Xuan Gao Ke

Established in May 2006, Guoxuan High-tech Co., Ltd. is one of the earliest enterprises engaged in independent research and development, production and sales of lithium-ion batteries for new energy vehicles in China. The company's main products are lithium iron phosphate materials and batteries, ternary materials and batteries, power battery packs, battery management systems and energy storage battery packs. The products are widely used in the field of pure electric passenger cars, commercial vehicles, special vehicles, light vehicles and other new energy vehicles, while providing system solutions for energy storage power stations, communication base stations, etc.

In May 2022, the company released its first semi-solid cell product. Through the solid electrolyte composite positive electrode (LATP coating), solid electrolyte functional ion membrane, monomer in-situ solid-state technology, silicon doped lithium, composite fluid collection and other processes, the monomer energy density is 360Wh/kg, and the Pack energy density is 260Wh/kg. The battery pack of the matching model has a capacity of 160kwh and a driving range of more than 1000km. In terms of production capacity, the semi-solid production capacity is about 1gwh by the end of 2022, and a larger semi-solid production line will be officially put into operation in 2023 H1.

The company has 400Wh/kg ternary semi-solid battery laboratory prototype samples, the future will also through technological innovation to land silicon based negative iteration, lithium metal negative and pre-lithium technology, accelerate the transition of liquid batteries to semi-solid, and finally achieve all-solid. The goal is to make an all-solid-state battery with an energy density of 800Wh/L+, corresponding to 400Wh/kg+ and 800 cycles after 25 years, using lithium-rich materials, sulfur series or other positive electrode materials, and using lithium negative electrode and interface modification technology to create an internal series of high-voltage mode-free battery pack. The overall goal of Guoxuan Gaoke solid-state battery is shown in the following table:

(6)Hive energy

Hive Energy was incorporated in 2018, and its subsidiary, Hive Japan, focuses on solid-state batteries and cutting-edge technology development. In terms of semi-solid batteries, the company's jelly batteries use safety coating and gel electrolyte technology to achieve high ionic conductivity (close to the electrolyte level) and high flame retardant (non-flammable in air). The first generation cell has various forms, including square short knife (230Wh/kg), soft pack cell (270Wh/kg), cycle life of more than 2000 times, the second generation cell is intended to complete 300-350Wh/kg technology development, is expected to choose polymer + oxide route, is currently in the pilot stage. In terms of all-solid-state batteries, the ionic conductivity of 10mS/cm, electrolyte film thickness of 20μm, energy density of 350-400Wh/kg, cycle life of 1000 times, has successfully passed the experimental tests such as acupuncture and 200℃ hot box, and is currently in the sample stage.

(7)Wei Blue new energy

Beijing Weilan New Energy Technology Co., Ltd. is a national high-tech enterprise focusing on the research and development and production of all-solid-state lithium batteries, with a series of core patents and technologies. It was jointly founded by Chen Liquan, academician of the Chinese Academy of Engineering, Li Hong, researcher of the Institute of Physics of the Chinese Academy of Sciences, and Yu Huigen, former chief engineer of BAIC New Energy. It is the only industrialization platform of solid state battery technology in Clean Energy Laboratory of Institute of Physics, Chinese Academy of Sciences. To undertake all related patents, R & D strength is leading, and has been invested by Xiaomi Group, NIO Capital, Huawei Hubo, Tianqi Lithium, Geely Holding, etc. The company's main semi-solid route, using polymer + oxide (LATP) composite route, the first eight core processes such as in-situ solid-state, improve solid-state interface contact, and is basically compatible with liquid battery process.

The preparation process of Weilan new energy semi-solid cell is shown in the following figure:

Weilan has continuously improved its industrial layout and has four production bases in Fangshan, Beijing, Liyang, Jiangsu, Huzhou, Zhejiang and Zibo, Shandong. In March 2019, the foundation of the solid-state battery phase I project was laid, with a total investment of 500 million yuan and a project investment of 180 million yuan. In December 2021, Njie, Beijing Weilan and Tianmu jointly built a solid electrolyte coating diaphragm project with a total investment of 1.3 billion yuan. In February 2022, Beijing Weilan 100GWH solid-state lithium battery project started, with a total investment of 40 billion yuan. In November 2022, Huzhou Base cargo-level solid state power cell industrialization engineering project completed the construction of the base plant and production line.

In August 2020, the pilot line of the company's Liyang Base was put into operation (0.2gwh), aiming at consumer areas such as drones and AGVs, with an energy density of 275Wh/kg and support for 7C high power discharge. In June 2022, the company put into production in Huzhou base (2gwh), aiming at the power field, the energy density reached 360Wh/kg, and began large-scale mass production in the first half of 23 years, the 150kwh battery pack equipped with NIO ET7 was launched, the driving range exceeded 1000km, the cost was more expensive, and the scale effect and research and development breakthrough were still needed to further reduce the cost. In addition, the company has developed iron lithium energy storage cell, with intrinsic safety attributes, energy density 150Wh/kg, has begun demonstration application (4MWh). In terms of all-solid-state batteries, the company plans to launch 400 and 500Wh/kg products in 24 and 25 years, and the mass production progress is relatively ahead.

Weilan has a production capacity of 2.2gwh by the end of 2022, and a long-term production capacity planning of over 50GWh. The company's electrolyte and Tianmu Lead, blue Gu new energy, alliance Guli cooperation, positive pole with Rongbai, Dang Sheng signed a strategic cooperation agreement, negative pole with Tianmu Lead, Betrie, Tianqi Lithium cooperation, diaphragm signed with Njie shares, forming a perfect industrial chain layout.

Note: This article cites data and images from the Internet