Lying Cell - MG Cyberster Cube Battery

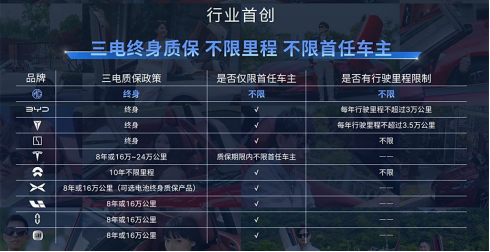

Recently, MG brand launched the "Super Anxin Promise" for its new energy vehicle models' three electric systems, which is not limited to car owners or mileage. It provides a lifetime warranty for customers' non operational vehicles' three electric systems. If the vehicle catches fire due to the three electric system's own reasons, the official will unconditionally replace the customer's car within 20 working days (with a new car with the same configuration as the original car or an equivalent new car). Today we will learn about the MG Cyberster Rubik's Cube battery.

The Super Anxin Promise is the latest owner's benefit launched by SAIC, which covers non operational vehicle owners of multiple models under SAIC's MG and Roewe brands, including Roewe D7 EV, D7 DMH, D5X DMH, iMAX8 EV, as well as MG4 EV and MG Cyberster.

A protruding metal component is installed at the bottom of the front subframe of the MG Cyberster chassis, mainly to protect the battery pack. When the vehicle rushes towards obstacles such as protruding rocks on the road surface at high speed, this protruding metal component will collide with the obstacle before the battery pack, thereby reducing the damage to the battery pack support.

The Cyberster has a shallow tunnel in the center of the bottom of the car, which is used to arrange high-voltage lines and coolant pipelines. Similar arrangements are not common. The pipeline and wiring both lead to the rear motor. Like most mainstream new energy vehicles, the Cyberster's threshold beam is very wide and thick, which can provide protection for the battery pack in the event of a collision accident.

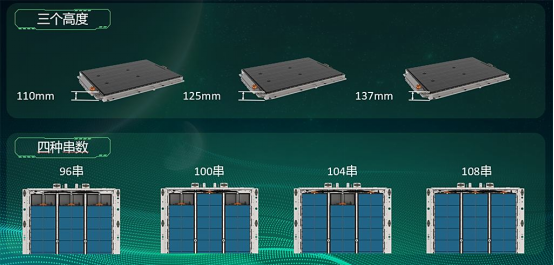

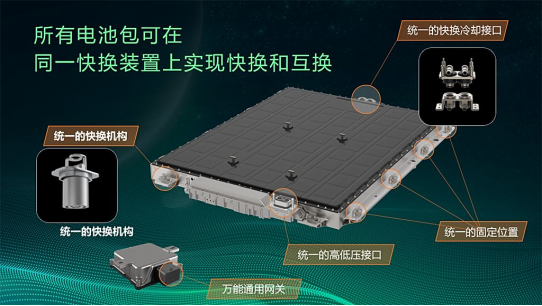

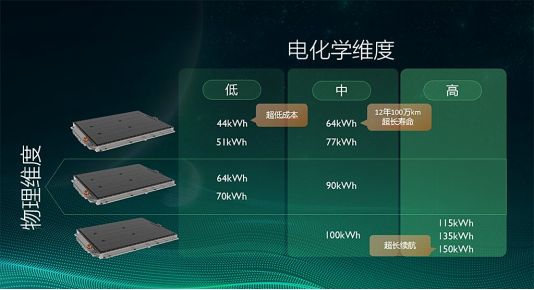

Some of SAIC's pure electric vehicle products use battery technology called "Rubik's Cube Battery". Firstly, the length and width of the SAIC Magic Cube battery are 1690mm and 1300mm respectively, with fixed dimensions of 110mm, 125mm, and 137mm in thickness. The MG Cyberster uses a thickness of 110mm. At the same time, the internal battery cells of the battery pack can be connected in series in four designs: 96 series, 100 series, 104 series, and 108 series, to form battery pack models with different capacities.

In addition to its structural layout, the Rubik's Cube battery also supports different electrochemical systems, ranging from high-energy density semi-solid batteries to relatively low energy density lithium iron phosphate batteries, all of which are on the support list. According to data, the capacity of Rubik's Cube batteries covers a wide range of 44kWh to 150kWh. The battery pack capacity of MG Cyberster varies depending on the vehicle model, with two options: 64kWh and 77kWh.

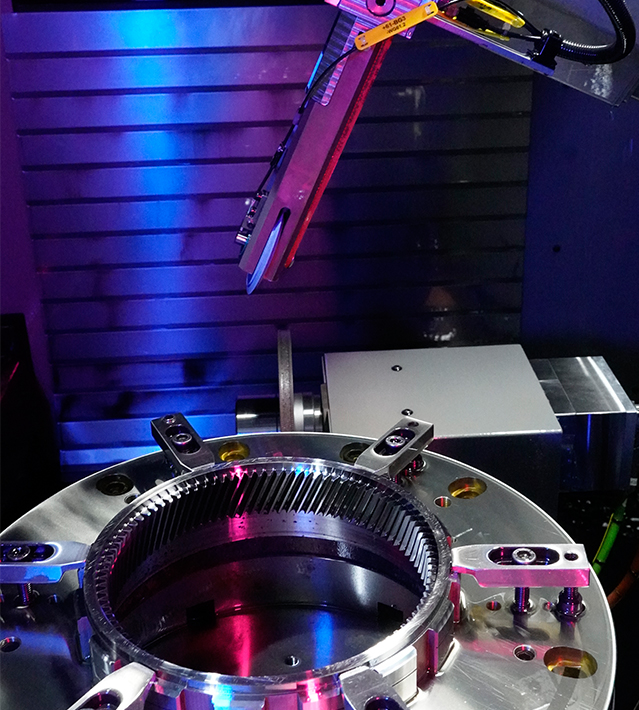

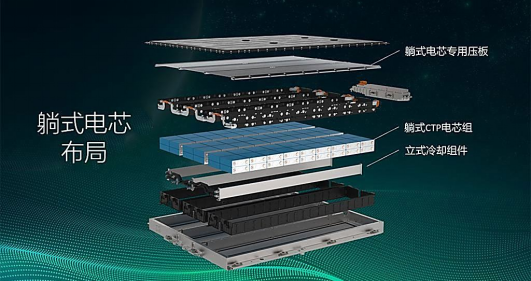

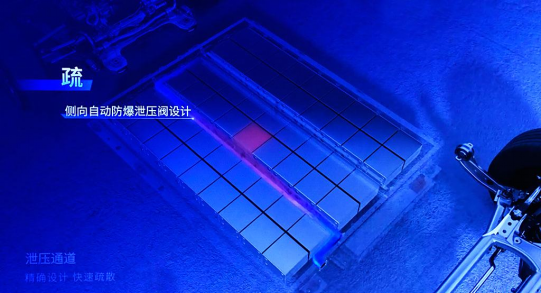

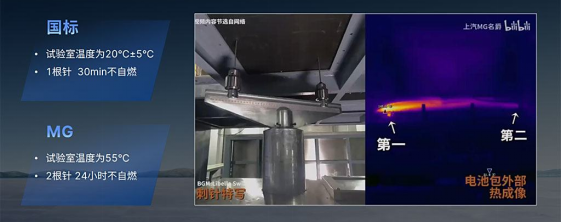

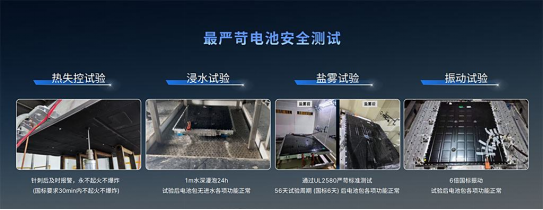

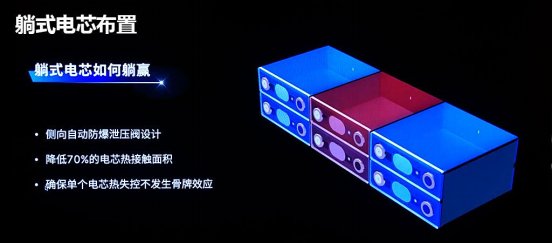

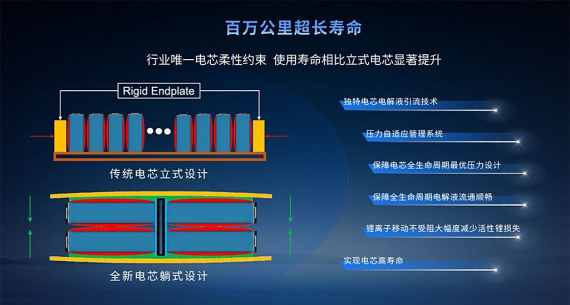

Layout of lying battery cells: special pressure plate for lying battery cells, lying CTP battery cell group, and vertical cooling components. Another characteristic of the Rubik's Cube battery is that the internal cells of the battery pack are placed lying down, with the positive and negative electrodes and pressure relief valves facing the side. When the cells experience thermal runaway, high-temperature electrolyte will spray out to both sides of the module.

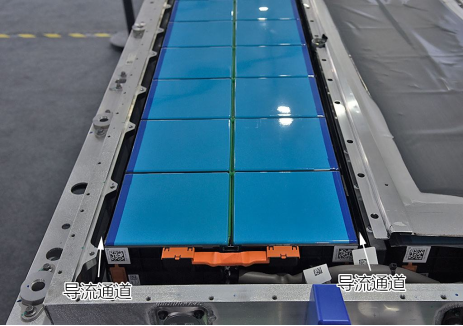

When the battery cell loses control of heat, the high-temperature and high-pressure electrolyte vapor inside is discharged through the pressure relief valve on the end face of the battery cell, and then flows through the above-mentioned diversion channel. Finally, it is discharged outside the battery pack through the pressure relief valve on the battery pack shell.

The front and rear faces of the battery pack housing are equipped with pressure relief valves to ensure that the high-temperature and high-pressure electrolyte inside the battery pack can be released in a timely and rapid manner, avoiding heat accumulation inside the battery pack and igniting other cells.

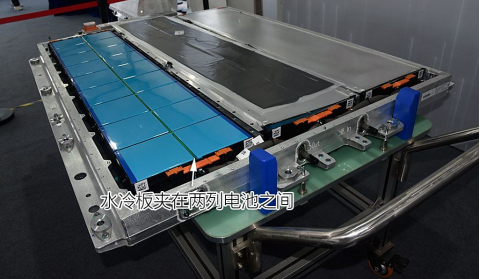

The battery cell cooling system adopts a water-cooled form for the Rubik's Cube battery cells. The three modules in the battery pack are equipped with independent vertically arranged water-cooled plates, which are arranged at the bottom end face of the battery cell. There is a thermal conductive material between the water-cooled plate and the battery to further improve the heat exchange efficiency.

The contact area between two stacks of battery cells is smaller compared to traditional vertical layout designs, which to some extent delays the heat spread between the cells and provides users with more escape time in emergency situations. Compared to the vertical layout design, the heat spread presents a radiating pattern towards the surroundings.

During the charging and discharging process, the volume of a battery cell will expand or contract. On the Rubik's Cube battery, the volume change of the lying cell is compensated for by a highly flexible structural adhesive. This structural adhesive was developed in collaboration between SAIC and Dow Chemical, which balances bonding strength and flexibility, catering well to the volume changes of battery cells during operation, thereby extending their service life.

Overall, SAIC Magic Cube Battery has enhanced the safety performance of the battery by cleverly arranging the battery cells, delaying the thermal spread of the cells, and reducing the thickness of the battery pack, compared to traditional vertical cell layouts.

Note: The data and images cited in the article are sourced from the internet